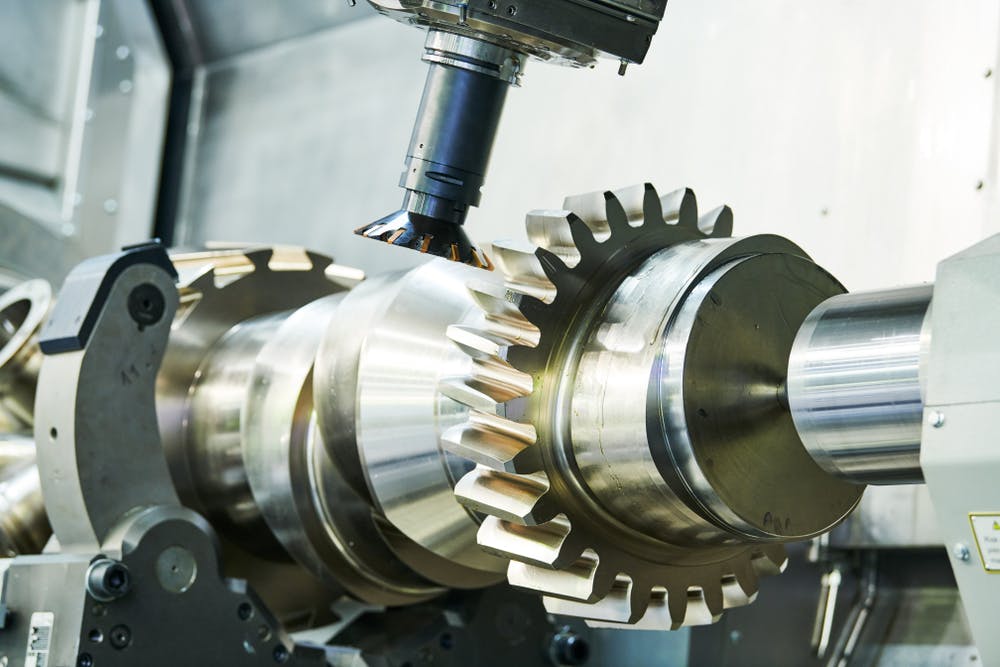

The term "gear hobbing

machine" describes a tool that can cut and shape gears. The machine

gradually grinds the gear's teeth while spins the shaft quickly. It is not

uncommon for many bags to be cut simultaneously. Therefore, they are ideal for

tasks that need precision and efficiency. Reduced expenses, increased output,

and enhanced accuracy are just a few benefits of a gear milling cutter.

Implements For Broaching

Broaching, which entails removing

forms, is the most common method for making gears. When using a broach to cut

anything, this is the usual result. By progressively running a broach over each

tooth, its size is increased.

Slackening Down

If you want to make gears quickly and

efficiently, try "hobbling" them. The spiral cutting tool, also known

as a hob, is used to etch teeth onto blanks in a gear hobbing machine. This

technology works well for moderate to high output, and its speed makes it ideal

for mass manufacturing.

Cutting Gear Tools Have AWide Variety

Of Applications

The hob is among the most versatile

tools for cutting bags because of its many cutting teeth and ability to produce

various gears. The rotational speed and angle of the hob concerning the

workpiece establish the kind and quantity of teeth made by the gearbox. So,

hobbies are a great way to spend leisure time without breaking the bank.

Rolling Pins

A milling machine's form cutter is

used to shape the gear teeth. This cutter rotates axially to cut gear teeth to

exact specifications. A tooth cut by the blade allows the gear cutting tools manufacturers to move to the next

position. Once the blank is blank again, the form cutter starts missing the

next tooth, and the process continues until all teeth are ready.

The Cutting OfTemplet Gear

A single-pointed cutting tool might

be used to create a gear tooth profile. An inverted temple shaped like a gear

tooth controls the device's rotation and guides it along a set path while

making gear-cutting tools.

Manufacturing Machinery ForBevel Gear

Eight or nine bevel gears were

manufactured for each position by the uncoated tool. Nevertheless, using the

same cutting settings, the tin-coated devicecreated 24 to 26 bevel packs in each

location. There has been an increase in production of about three times this

level.

The main reason for this is that a

wear-resistant tin coating was applied. This coating prevents chemicals and

heat from penetrating. The layer doubles as a lubricant thanks to its low

coefficient of friction. The tool has a longer lifetime with this coating since

it is more heat stable than the untreated one. It further boosts productivity.

The development of novel tool

materials has been expedited due to the need for technological progress and

economic competitiveness. Many different kinds of materials have been tested to

achieve this goal.

The materials that have endured and

are still available are the best options when considering tool life, metal

removal rate, surface finish produced, ability to perform satisfactorily in

various applications, and cost of tools made from them. These materials should

have the necessary properties for devices, such as chemical stability,

toughness, wear resistance, and hot hardness.

Tools may be made from various

materials, such as diamond, HSS, ceramics, cermet, cemented carbide, and cubic

boron nitride. Regardless of these materials, HSS and cemented carbide cutters

and tools are the most challenging for gear cutting. The cutting speed is

affected by the low heat stability of both materials, slowing production.

.jpg)

0 Comments